Sorooshian On Team Working to Develop Medical Masks During COVID-19

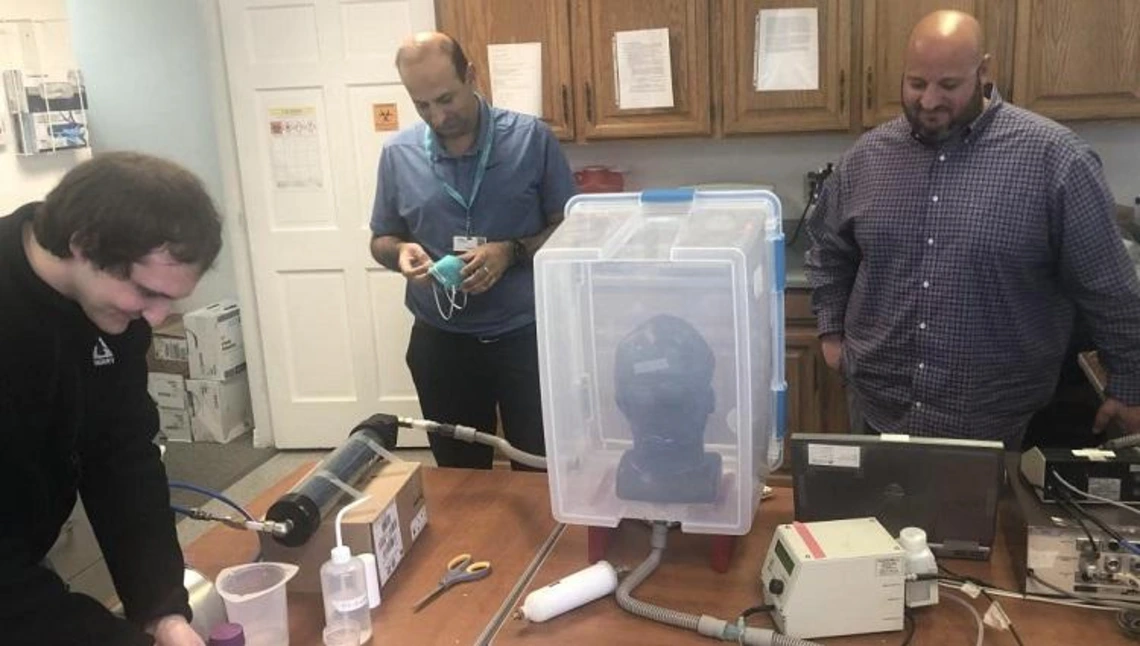

An interdisciplinary team of University of Arizona researchers are working to 3D-print medical masks for local hospitals in need of personal protective equipment.

The team includes CHEE professor Armin Sorooshian, Doug Loy and Krishna Muralidharan from the Department of Materials Science & Engineering, and Sairam Parthasarathy of the Department of Medicine.

Amid the COVID-19 pandemic, hospitals across the world are running short on personal protective equipment, including N95 respirators – masks that, unlike surgical masks, fit tightly around the face and are capable of filtering out 95% of airborne particles.

Loy and Muralidharan are working on the design and printing of the masks. Parthasarathy, a medical doctor, and Sorooshian, who studies aerosol particles in the atmosphere, will test how well the masks keep out harmful biological particles, to ensure they meet the standards of the National Institute for Occupational Safety and Health.

"We want to design masks that we can print relatively quickly and make them into a form that people will want to use, so it should wear similarly to the N95 mask," Loy said, who also has a joint appointment in the Department of Chemistry and Biochemistry. "We're finding a lot of designs online that may look good, but they either require the assembly of dozens of parts or they would take forever to print, which drove our decision to take a different approach."

In an interview with Tucson Local Media, Loy discussed how designing and printing new masks gives MSE students real-world problem-solving experience.

“It’s great for the students, because they’re learning more than just from textbooks. They’re doing designs, building prototypes and testing them and stepping up all the way into manufacturing,” Loy said. “This is a pretty invaluable experience for them.”

The UA recently ordered 10 additional 3D printers to help with the project, which should increase the team's ability to print more than 1000 masks per week. The masks are being printed with polylactic acid and modeled to fix problems with the current N95s.

“A lot of them, the fit isn’t good, so it leaks around the edges, they’re uncomfortable, and a good fraction take too long to print and are overly complicated,” Loy said. “So we’re looking at very simple designs with good fits, good sealing properties, comfortable, and we’re even looking for better designs for the straps.”

"These researchers are developing prototypes that could be printed out in communities all over the world facing medical supply shortages," said David Hahn, Craig M. Berge Dean of the College of Engineering. "We are proud that faculty are working at the intersection of engineering and medicine to rise to the challenge this crisis presents."

See Loy and Parthasarathy discuss this work in a news clip by KVOA.